hardness test using durometer|what is a durometer material : broker Durometer is a metric used to quantify the hardness or resistance to indentation of materials. It provides a numerical value that indicates the material’s ability to withstand deformation under an applied force. Conheça o Kumon O Kumon é uma metodologia que visa inc.

{plog:ftitle_list}

LABORATÓRIO DOM BOSCO. CONTATO. Central de Atendimento: (21) 2719-9438. (21) 2828-0025. WhatsApp: (21) 99004-6794. Email: .

Durometer is a metric used to quantify the hardness or resistance to indentation of materials. It provides a numerical value that indicates the material’s ability to withstand deformation under an applied force.

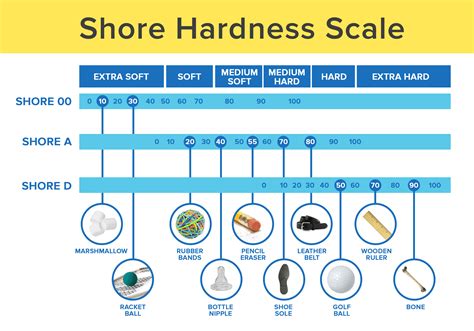

Durometer is a self-referencing scale that compares the hardness of a particular group of materials: elastomers and plastics. There are a number of durometer or Shore durometer scales but Shore A and Shore D are by far the most useful . Durometer is a standardized way of measuring the hardness of materials like rubber or plastic. Hardness is a measure of how resistant a plastic is to deformation caused by mechanical indentation or abrasion. Engineers .

By accurately measuring the hardness of materials, durometers facilitate the production of rubber products with consistent performance, help evaluate the suitability of plastics for specific applications, and ensure the . The Shore A hardness (durometer) scale is one of many durometer scales used to measure material hardness. Shore A durometers range from 0 to 100 — the higher the durometer value, the harder the material.

Shore Durometer hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Shore Duromter A and D scales of hardness are commonly used for rubber and 'soft' polymers such as .Durometer hardness is dependent on the elastic modulus and viscoelastic behavior of the material being tested. Inferences are often drawn between durometer hardness and other physical characteristics of the material being . The ASTM D2240 standard outlines the test procedure for measuring the hardness of elastomers using a durometer. The test involves measuring the depth of penetration of a .The most basic test for measuring the hardness of a material is using an analog handheld durometer. Pressure should be applied gradually to the rubber using the durometer. It is important to apply pressure evenly and without shock .

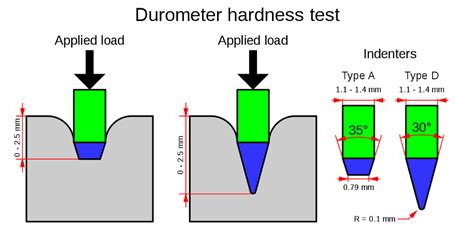

How the test works Shore hardness (also known as 'Durometer hardness') is determined by measuring the penetration of the Durometer's spring loaded indenter into the sample. The operator applies the instrument to the sample . how to use a durometer. Pass the durometer around with a selection of samples, keep the results a

The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . The chart also gives users a good understanding of the best types of rubbers and plastics to use based on .The hardness of plastics is most commonly measured by the Shore® (Durometer) test or Rockwell hardness test. Both methods measure the resistance of plastics toward indentation and provide an empirical hardness .Thicker coatings are typically measured using an indentor-type tester such as a Durometer (ASTM D2240, Standard Test Method for Rubber Property – Durometer Hardness), which measures the resistance to indentation under a specific spring force load. The project specification should indicate the appropriate type of hardness testing (Pencil or .

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

Rubber hardness testing, conducted using durometers, ensures consistent quality standards in rubber production. It aids in the evaluation of the abrasion resistance of rubber compounds, an important characteristic of materials used in tires, seals, gaskets, and other rubber products. Furthermore, durometer testing helps assess the sealing .The most basic test for measuring the hardness of a material is using an analog handheld durometer. Pressure should be applied gradually to the rubber using the durometer. It is important to apply pressure evenly and without shock load to the indenter. Shock load is a sudden and drastic increase in load, so maintaining consistent pressure is key. Shore durometer is designed for vulcanized rubber and plastic hardness testing. The A scale for rubbers in the normal-hardness range. Shore A Durometer Teste. Determining the hardness of a material can be done by using a durometer tester. In this video, we demonstrate how to use this device with different types of .

Durometer testing is used to determine the hardness of thermoplastic elastomers, vulcanized rubber, elastomeric materials, cellular materials, gel-like materials, and other plastics that are unsuitable for measurement by conventional Rockwell or microindentation hardness testing. The durometer apparatus measures the deflection of a calibrated .If the value displayed by the durometer does not conform to the tolerance of the test block value (for example 25 +/- 5, which means that the displayed hardness value obtained on the test block can range from 20-30), the durometer should not be used to measure the hardness of a coating and should be returned to the manufacturer or service .CCSi DuroMatters: Durometer Instrument Background. The material is generally termed “rubber or rubber—like”. Specifically, ASTM D2240 durometer hardness testing is restricted to thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, cellular materials, and some plastics as defined by the ASTM Committee on Terminology in ASTM D1566.

is the texes generalist 4-8 test hard

Welcome to our ASTM D2240 testing services page for evaluating “Shore hardness” as part of our analysis of plastics and polymers.This standard, ASTM D2240, also known as “Rubber Property—Durometer Hardness,” allows for the measurement of a material’s hardness by indenting the material with a standardized tip under a defined force.The Metal Hardness Testing Durometer PCE-2600N-ICA is used wherever a fast hardness test has to be carried out. It is possible to use the durometer PCE-2600N-ICA to determine the surface hardness of many metals. The durometer PCE-2600N-ICA is especially suitable for quality or product inspection. Measurement according to Leeb Rebound method Significance and Use 4.1 This test method is based on the penetration of a specific type of indentor when forced into the material under specified conditions. The indentation hardness is inversely related to the penetration and is dependent on the elastic . Standard Test Method for Rubber Property—Durometer Hardness D2240-15R21 ASTM|D2240 .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the . Durometer is a measurement of hardness and like other hardness test measures the depth of indentation in the material created by a given Force using a standa. USA Testing Lab for ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness in USA, Indonesia, Philippines, Malaysia, Thailand, Canada, China, India, and all over the World. (302)244-7710 . . All the tests are done at well-equipped testing laboratories using standard testing methods for best output and satisfaction.

Choose a scale that is appropriate for the material you are testing. The durometer dial reads from 0 to 100 points. Readings less than 10 or above 90 should be avoided. If more than 90 points in A scale, use D scale. If less than 10 points in D scale, use A scale. Use other scales to obtain a reading closer to 50 points. In this video, an Instrument Choice Scientist demonstrates how to test the hardness of materials using a digital durometer.View the Shore A Digital Durometer.Durometer Operating Stands; Durometer Test Block Kits; Multi-Scale Durometers; O-Ring Hardness Kits; Slim Probe Durometers; Reconditioned Durometers; Data Output Cable . Rex Gauge has been a leader in the durometer hardness gauge industry for over 80 years. Rex Gauge Durometers are available in ASTM D 2240 durometer types (Shore hardness): A .

The term durometer is often used to refer to the measurement as well as the instrument itself. The durometer scale was defined by Albert F. Shore, who developed a measurement device to measure Shore hardness in the 1920s. Durometer is typically used as a measure of hardness in polymers, elastomers, and rubbers.ASTM D2240 durometers allow for a measurement of the initial hardness, or the indentation hardness after a given period of time. The basic test requires applying the force in a consistent manner, without shock, and measuring the hardness (depth of the indentation). If a timed hardness is desired, force is applied for the required time and then .%PDF-1.4 %âãÏÓ 1 0 obj /FormType 1 /Subtype /Form /Resources /Font /R8 2 0 R /Ft1 3 0 R >> /ProcSet [/PDF /Text] /ExtGState 4 0 R >> /Type /XObject /BBox [0 0 595 839] /Filter /FlateDecode /Length 283 /Matrix [1 0 0 1 0 0] >> stream xœu MoÂ0 †ïù ïmô ñ± lš4¦}äØK–˜¶¨MJšlb¿~ ²Ó„,Ë’í×ïã Ò!GzŠKU ½ÏPt,ÅcÌ‚ ?/àRTƒLÄ¥ù©!v¬×qÜrÌ cˆ† ˆ=Û ö ƒõ . Dr. Dmitri Kopeliovich Shore hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter. Hardness of Polymers (rubbers, plastics) is usually measured by Shore scales. Shore A scale is used for testing soft Elastomers (rubbers) and other soft polymers. Hardness of hard elastomers and most other polymer .

Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.

what is a durometer material

WEBTela Inteira. Jogo Online: Best Vacation Adventure Ever. Livre para todas as idades L. Polly e sua amiga foram passar as férias em um hotel repleto de atrações e muita .

hardness test using durometer|what is a durometer material